Difference Detection Matrix Example: Difference between revisions

No edit summary |

Lisa Hacker (talk | contribs) No edit summary |

||

| (25 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

'' | <noinclude>{{Banner Weibull Examples}} | ||

''This example appears in the [https://help.reliasoft.com/reference/life_data_analysis Life data analysis reference]''. | |||

Assume there are two design options for a new product. | </noinclude> | ||

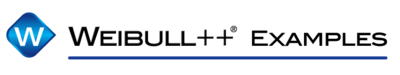

In this example, you will use the Difference Detection Matrix to choose the suitable sample size and duration for a reliability test. Assume that there are two design options for a new product. The engineers need to design a test that compares the reliability performance of these two options. The reliability for both designs is assumed to follow a Weibull distribution. For Design 1, its shape parameter <math>\beta = 3\,\!</math>; for Design 2, its <math>\beta= 2\,\!</math>. Their B10 lives may range from 500 to 3,000 hours. | |||

'''Solution''' | |||

''' | For the initial setup, set the sample size for each design to '''20''', and use two test durations of '''3,000''' and '''5,000''' hours. The following picture shows the complete control panel setup and the results of the analysis. | ||

[[Image:Detection Matrix Example Result.png|center|800px]] | |||

The columns in the matrix show the range of the assumed B10 life for design 1, while the rows show the range for design 2. A value of 0 means the difference cannot be detected through the test, 1 means the difference can be detected if the test duration is 5,000 hours, and 2 means the difference can be detected if the test duration is 3,000 hours. For example, the number is 2 for cell (1000, 2000). This means that if the B10 life for Design 1 is 1,000 hours and the B10 life for Design 2 is 2,000 hours, the difference can be detected if the test duration is at least 5,000 hours. | |||

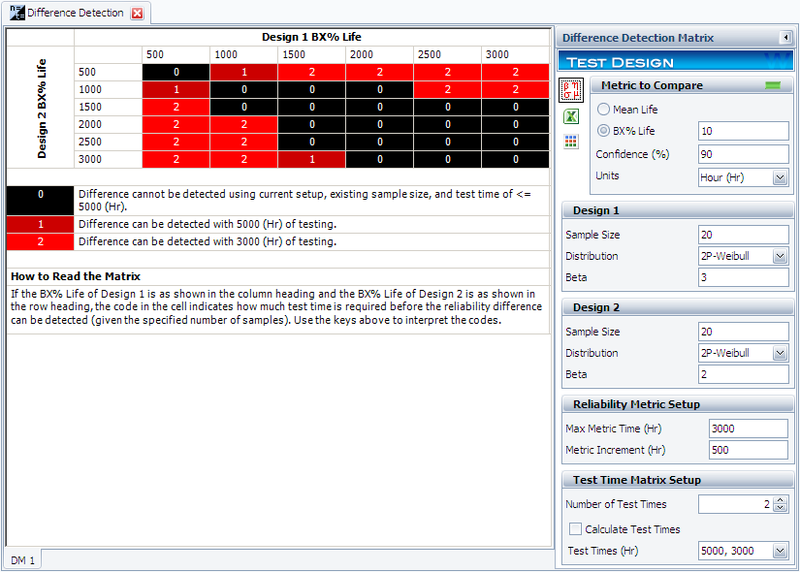

Click inside the cell to show the estimated confidence intervals, as shown next. By testing 20 samples each for 3,000 hours, the difference of their B10 lives probably can be detected. This is because, at a confidence level of 90%, the estimated confidence intervals on the B10 life do not overlap. | |||

[[Image: Detection Matrix Example B10 | [[Image:Detection Matrix Example B10 Intervals_new.png|center|550px]] | ||

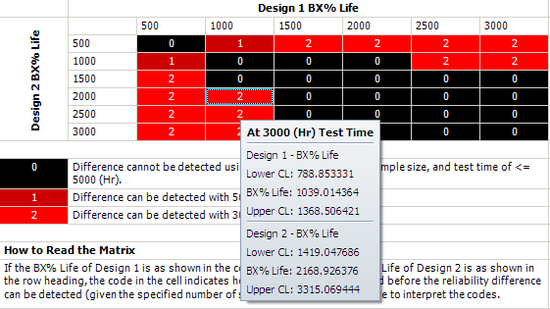

We will use Design 1 to illustrate how the interval is calculated. For cell (1000, 2000), Design 1's B10 life is 1,000 and the assumed <math>\beta\,\!</math> is 3. We can calculate the <math>\eta\,\!</math> for the Weibull distribution using the '''Quick Parameter Estimator''' tool, as shown next. | |||

[[Image:Detection Matrix Example Parameter Estimator.png|center|550px]] | |||

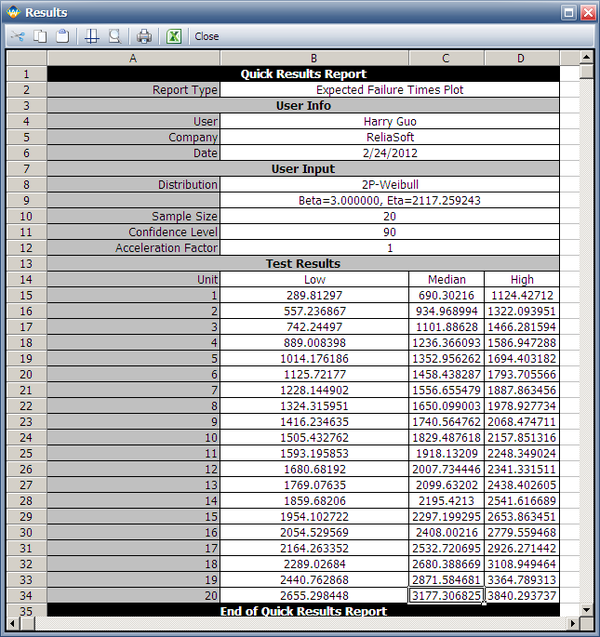

[[ | The estimated <math>\eta\,\!</math> is 2117.2592 hours. We can then use these distribution parameters and the sample size of 20 to get the expected failure times by using Weibull's [[Reliability_Test_Design#Expected_Failure_Times_Plots|Expected Failure Times Plot]]. The following report shows the result from that utility. | ||

[[Image: Detection Matrix Example Expected Failure Tiime.png | [[Image:Detection Matrix Example Expected Failure Tiime.png|center|600px]] | ||

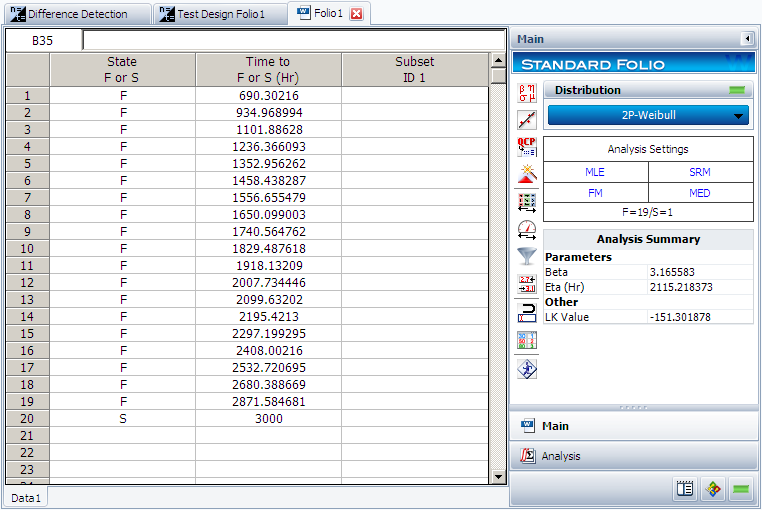

The median failure times are used to estimate the failure distribution. Note that since the test duration is set to 3,000 hours, any failures that occur after 3,000 are treated as suspensions. In this case, the last failure is a suspension with a suspension time of 3,000 hours. We can enter the median failure times data set into a standard Weibull++ folio as given in the next figure. | |||

[[Image: Detection Matrix Example B10 QCP.png.png | [[Image:Detection Matrix Example Std Folio Data.png.png|center|800px]] | ||

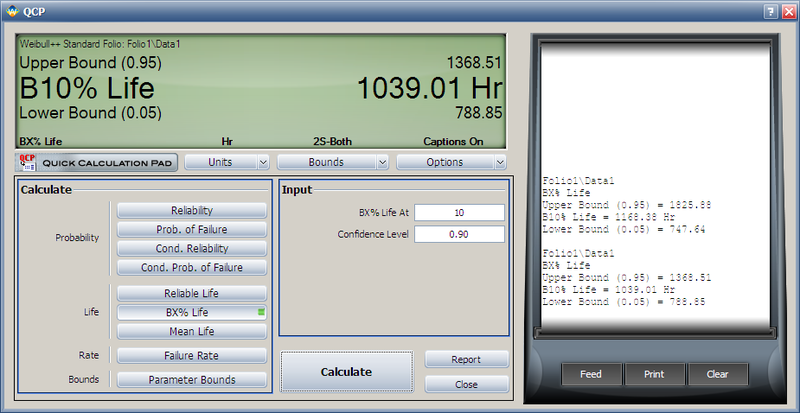

After analyzing the data set with the '''MLE''' and '''FM''' analysis options, we can now calculate the B10 life and its interval in the '''QCP''', as shown next. | |||

[[Image:Detection Matrix Example B10 QCP.png.png|center|800px]] | |||

From this result, we can see that the estimated B10 life and its confidence intervals are the same as the results displayed in the Difference Detection Matrix. | |||

The above procedure can be repeated to get the results for the other cells and for Design 2. Therefore, by adjusting the sample size and test duration, a suitable test time can be identified for detecting a certain amount of difference between two designs/populations. | |||

Latest revision as of 18:56, 18 September 2023

New format available! This reference is now available in a new format that offers faster page load, improved display for calculations and images and more targeted search.

As of January 2024, this Reliawiki page will not continue to be updated. Please update all links and bookmarks to the latest references at Weibull examples and Weibull reference examples.

This example appears in the Life data analysis reference.

In this example, you will use the Difference Detection Matrix to choose the suitable sample size and duration for a reliability test. Assume that there are two design options for a new product. The engineers need to design a test that compares the reliability performance of these two options. The reliability for both designs is assumed to follow a Weibull distribution. For Design 1, its shape parameter [math]\displaystyle{ \beta = 3\,\! }[/math]; for Design 2, its [math]\displaystyle{ \beta= 2\,\! }[/math]. Their B10 lives may range from 500 to 3,000 hours.

Solution

For the initial setup, set the sample size for each design to 20, and use two test durations of 3,000 and 5,000 hours. The following picture shows the complete control panel setup and the results of the analysis.

The columns in the matrix show the range of the assumed B10 life for design 1, while the rows show the range for design 2. A value of 0 means the difference cannot be detected through the test, 1 means the difference can be detected if the test duration is 5,000 hours, and 2 means the difference can be detected if the test duration is 3,000 hours. For example, the number is 2 for cell (1000, 2000). This means that if the B10 life for Design 1 is 1,000 hours and the B10 life for Design 2 is 2,000 hours, the difference can be detected if the test duration is at least 5,000 hours.

Click inside the cell to show the estimated confidence intervals, as shown next. By testing 20 samples each for 3,000 hours, the difference of their B10 lives probably can be detected. This is because, at a confidence level of 90%, the estimated confidence intervals on the B10 life do not overlap.

We will use Design 1 to illustrate how the interval is calculated. For cell (1000, 2000), Design 1's B10 life is 1,000 and the assumed [math]\displaystyle{ \beta\,\! }[/math] is 3. We can calculate the [math]\displaystyle{ \eta\,\! }[/math] for the Weibull distribution using the Quick Parameter Estimator tool, as shown next.

The estimated [math]\displaystyle{ \eta\,\! }[/math] is 2117.2592 hours. We can then use these distribution parameters and the sample size of 20 to get the expected failure times by using Weibull's Expected Failure Times Plot. The following report shows the result from that utility.

The median failure times are used to estimate the failure distribution. Note that since the test duration is set to 3,000 hours, any failures that occur after 3,000 are treated as suspensions. In this case, the last failure is a suspension with a suspension time of 3,000 hours. We can enter the median failure times data set into a standard Weibull++ folio as given in the next figure.

After analyzing the data set with the MLE and FM analysis options, we can now calculate the B10 life and its interval in the QCP, as shown next.

From this result, we can see that the estimated B10 life and its confidence intervals are the same as the results displayed in the Difference Detection Matrix.

The above procedure can be repeated to get the results for the other cells and for Design 2. Therefore, by adjusting the sample size and test duration, a suitable test time can be identified for detecting a certain amount of difference between two designs/populations.