Difference Detection Matrix Example

Test Design Using Life Difference Detection Matrix

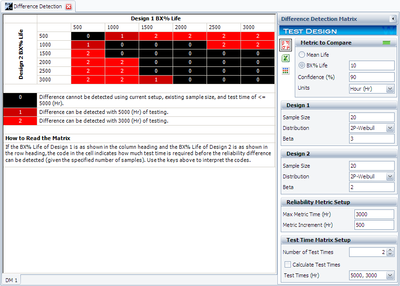

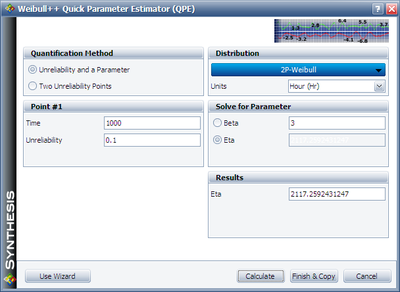

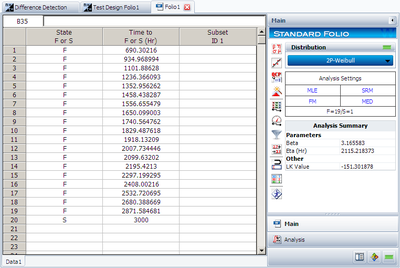

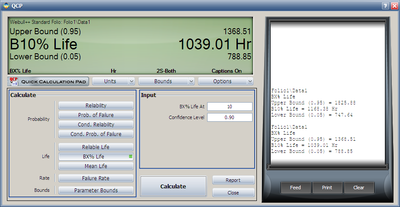

Assume there are two design options for a new product. Engineers need to design a test to compare the reliability perfomance of these two options. Both designs are assumed following Weibull distribution. For Design 1, its shape parameter [math]\displaystyle{ \beta }[/math] = 3; for Design 2, its [math]\displaystyle{ \beta }[/math] = 2. Their B10 lives may range from 500 to 3,000 hours. We want to use the Difference Detection Matrix to choose the suitable sample size and test duration.

Solution

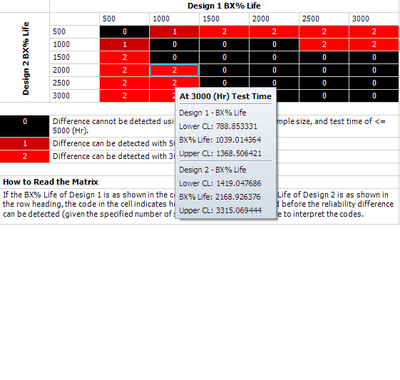

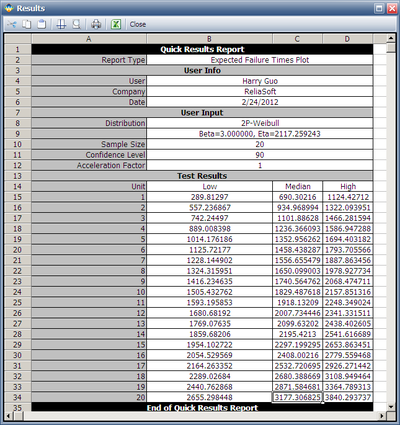

Initially, the sample size for each design is set to 20. Two test durations 3,000 and 5,000 also were chosen. Based on these settings and the assumptions on the failure time distributions, the following Difference Detection Matrix is obtained.

From the