Difference Detection Matrix Example

Test Design Using Life Difference Detection Matrix

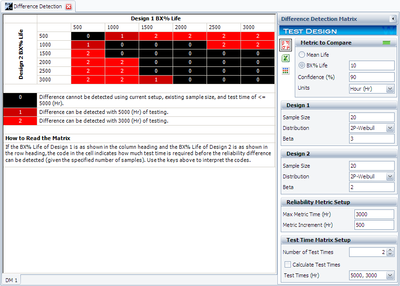

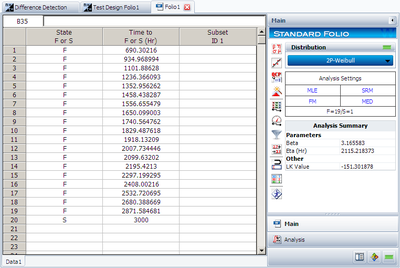

Assume there are two design options for a new product. Engineers need to design a test to compare the reliability perfomance of these two options. Both designs are assumed following Weibull distribution. For Design 1, its shape parameter [math]\displaystyle{ \beta }[/math] = 3; for Design 2, its [math]\displaystyle{ \beta }[/math] = 2. Their B10 lives may range from 500 to 3,000 hours. We want to use the Difference Detection Matrix to choose the suitable sample size and test duration.

Solution

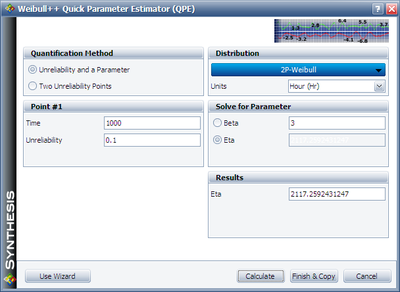

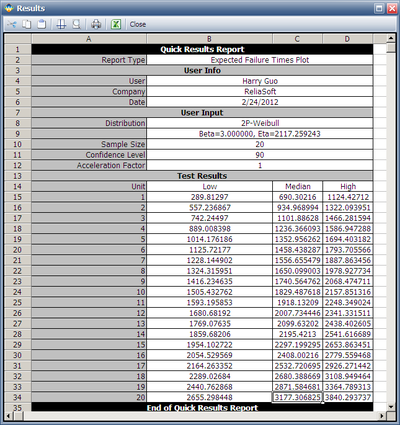

Initially, the sample size for each design is set to 20. Two test durations 3,000 and 5,000 also were chosen. Based on these settings and the assumptions on the failure time distributions, the following Difference Detection Matrix is obtained.

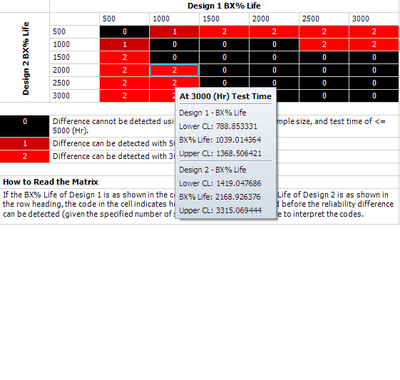

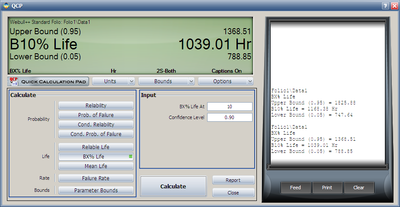

In the above figure, the range of the assumed B10 life for each design is from 500 to 3,000. The pair-wised comparison results are displayed in each cell. 0 means the difference cannot be detected through the test; 1 means the difference can be detected if the test duration is 5,000 hours; 2 means the difference can be detected if the test duration is 3,000 hours. For example for cell (1000, 2000), the number is 2. It means if the B10 life for design 1 is 1000 hours and the B10 life for design 2 is 2000 hours, by testing 20 samples each for 3,000 hours, the difference of their B10 lives probably can be detected. This is because at a confidence level of 90%, their estimaed confidence intervals of the B10 life do not overlap. This can be seen in the figure below.