Stress-Strength Analysis in Design for Reliability: Difference between revisions

Lisa Hacker (talk | contribs) No edit summary |

Lisa Hacker (talk | contribs) No edit summary |

||

| Line 4: | Line 4: | ||

: • Evaluate the current reliability. | : • Evaluate the current reliability. | ||

: • If the reliability does not meet the target reliability of 90%, | : • If the reliability does not meet the target reliability of 90%, determine what parameters would be required for the strength distribution in order to meet the specified target. | ||

Revision as of 19:13, 30 March 2012

Using Stress-Strength Analysis to Determine the Required Strength Distribution

Assume the stress distribution for a component is known and it is a Weibull distribution with beta=3 and eta=2000. For the current design, the strength distribution is also a Weibull distribution with beta =1.5 and eta=4000.

- • Evaluate the current reliability.

- • If the reliability does not meet the target reliability of 90%, determine what parameters would be required for the strength distribution in order to meet the specified target.

Solution

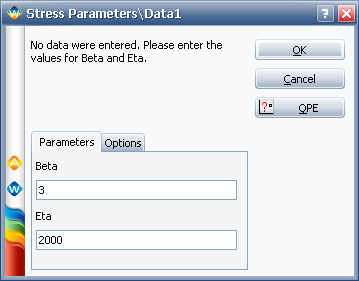

First, we need to create two empty Weibull++ standard folios and enter the distribution parameters for the stress and strength distributions. For example, for the stress distribution, it is:

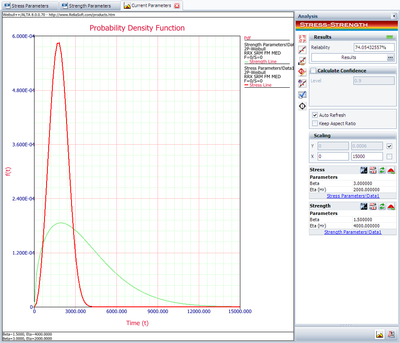

Then, following the steps given in Example 1, the reliability of the current design is given in the following figure:

The above result shows that the current reliability is about 74.05%, which is below the target value of 90%. We need to use the Target Reliability Parameter Estimator to determine the parameter for the strength distribution that would be required to meet the target. Click on the following icon:

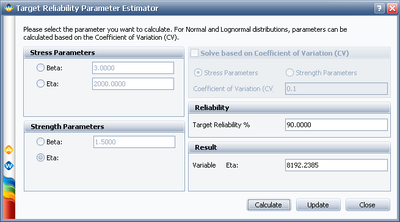

Choose to calculate for eta under Strength Parameters, set the Target Reliability to 90%, and click Calculate:

The calculated eta is 8192.2385 hours. Click Update to perform the stress-strength analysis again using the altered parameters for the strength distribution.

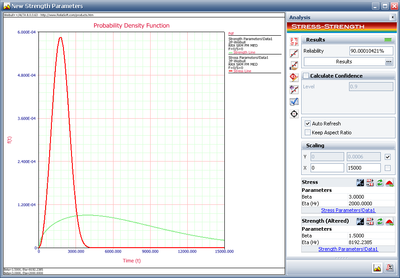

The plot shows the calculated reliability indeed is 90%.

Therefore, in order to meet the reliability requirement, the component must be redesigned with the eta to be at least 8192.2385 hours.