Template:BS Reliability Block Diagrams

Reliability Block Diagrams (RBDs)

Block diagrams are widely used in engineering and science and exist in many different forms. They can also be used to describe the interrelation between the components and to define the system. When used in this fashion, the block diagram is then referred to as a reliability block diagram (RBD).

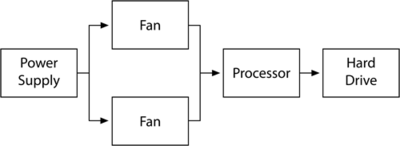

A reliability block diagram is a graphical representation of the components of the system and how they are reliability-wise related (connected). It should be noted that this may differ from how the components are physically connected. An RBD of a simplified computer system with a redundant fan configuration is shown in Figure 2.2.

Reliability Blocks

RBDs are constructed out of blocks. The blocks are connected with direction lines that represent the reliability relationship between the blocks.

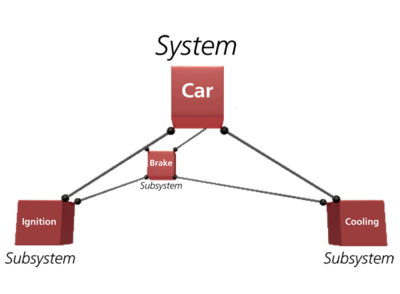

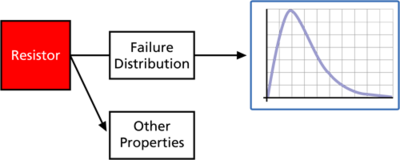

A block is usually represented in the diagram by a rectangle. In a reliability block diagram, such blocks represent the component, subsystem or assembly at its chosen black box level. Figure 2.3 shows two blocks, one representing a resistor and one representing a computer.

It is possible for each block in a particular RBD to be represented by its own reliability block diagram, depending on the level of detail in question. For example, in an RBD of a car, the top level blocks could represent the major systems of the car, as illustrated in Figure 2.4. Each of these systems could have their own RBDs in which the blocks represent the subsystems of that particular system. This could continue down through many levels of detail, all the way down to the level of the most basic components (e.g. fasteners), if so desired.

The level of granularity or detail that one chooses should be based on both the availability of data and on the lowest actionable item concept. To illustrate this concept, consider the aforementioned computer system (Figure 2.2). When the computer manufacturer finds out that the hard drive is not as reliable as it should be and decides not to try to improve the reliability of the current hard drive but rather to get a new hard drive supplier, then the lowest actionable item is the hard drive. The hard drive supplier will then have actionable items inside the hard drive, and so forth.

Block Failure Models

Having segmented a product or process into parts, the first step in evaluating the reliability of a system is to obtain life/event data concerning each component/subsystem (i.e. each block). This information will allow the reliability engineer to characterize the life distribution of each component. Data can be obtained from different sources, including:

- In-house reliability tests.

- Accelerated life tests.

- Field data.

- Warranty data.

- Engineering knowledge.

- Similarity to prior designs.

- Other reference sources.

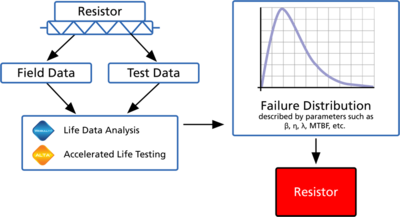

Additionally, component life data may also be provided by the manufacturer or supplier of the component/subsystem. Once the data set has been obtained, the life distribution of a component/subsystem can be estimated using ReliaSoft's Weibull++ or ALTA software. For example, consider a resistor that is part of a larger system to be analyzed. Failure data for this resistor can be obtained by performing in-house reliability tests and by observing the behavior of that type of resistor in the field. A life distribution is then fitted to the data and the parameters are obtained (Figure 2.5). The parameters of that distribution represent the life distribution of that resistor block in the overall system RBD.

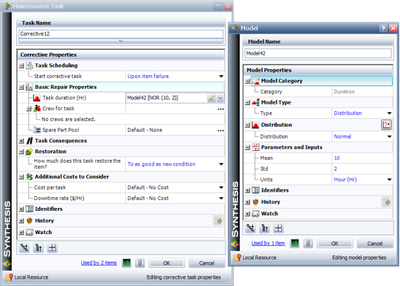

In the same manner, other types of information can also be obtained that can be used to define other block properties, such as the time-to-repair distribution (by analyzing the times-to-repair of each block instead of the times-to-failure), other maintenance requirements, throughput properties, etc.

These block properties can then be used to perform a variety of analyses on the overall system to predict and/or optimize the system's reliability, maintainability, availability, spare parts utilization, throughput, etc.

Available Distributions

Since the failure properties of a component are best described by statistical distributions, the most commonly used life distributions are available in BlockSim. The available distributions are:

- 1 and 2 parameter exponential distributions.

- 1, 2 and 3 parameter Weibull distributions.

- Mixed Weibull distributions (with 2, 3 or 4 subpopulations).

- Normal distribution.

- Lognormal distribution.

- Generalized-Gamma (i.e. G-Gamma) distribution.

- Gamma distribution.

- Logistic distribution.

- Loglogistic distribution.

- Gumbel distribution.

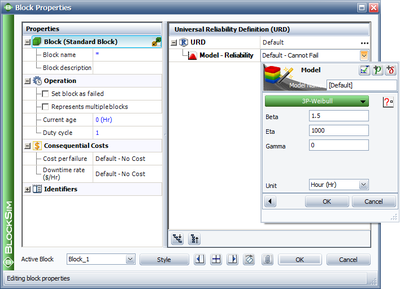

The same distributions are also available as repair distributions and in other probabilistic property windows that we will discuss later. Figure Ch2fig6 illustrates the Block Properties window with the Weibull distribution assigned as the failure distribution. Figure Ch2fig7 illustrates the Block Properties window with the normal distribution assigned as the repair distribution.

The System Reliability Function

After defining the properties of each block in a system, the blocks can then be connected in a reliability-wise manner to create a reliability block diagram for the system. The RBD provides a visual representation of the way the blocks are reliability-wise arranged. This means that a diagram will be created that represents the functioning state (i.e. success or failure) of the system in terms of the functioning states of its components. In other words, this diagram demonstrates the effect of the success or failure of a component on the success or failure of the system. For example, if all components in a system must succeed in order for the system to succeed, the components will be arranged reliability-wise in series. If one of two components must succeed in order for the system to succeed, those two components will be arranged reliability-wise in parallel. Chapter 4 discusses RBDs and diagramming methods.

The reliability-wise arrangement of components is directly related to the derived mathematical description of the system. The mathematical description of the system is the key to the determination of the reliability of the system. In fact, the system's reliability function is that mathematical description (obtained using probabilistic methods) and it defines the system reliability in terms of the component reliabilities. The result is an analytical expression that describes the reliability of the system as a function of time based on the reliability functions of its components. Chapters 3, 4 and 5 discuss this further. These chapters also offer derivations of needed equations and present examples.