Two Level Optimum Test Plan for One Stress: Difference between revisions

Jump to navigation

Jump to search

Kate Racaza (talk | contribs) (Created page with '{{Reference Example|ALTA_Reference_Examples_Banner.png|ALTA_Reference_Examples}} This example compares the results for the 2-Level Statistically Optimum test plan for one stress…') |

Kate Racaza (talk | contribs) No edit summary |

||

| (6 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

{{Reference Example| | {{Reference Example|{{Banner ALTA Reference Examples}}}} | ||

This example | This example validates the results for the 2 level statistically optimum test plan for one stress in ALTA. | ||

{{Reference_Example_Heading1}} | {{Reference_Example_Heading1}} | ||

The data set is from Example 20.5 on page 542 in the book | The data set is from Example 20.5 on page 542 in the book ''Statistical Methods for Reliability Data'' by Dr. Meeker and Dr. Escobar, John Wiley & Sons, 1998. | ||

{{Reference_Example_Heading2}} | {{Reference_Example_Heading2}} | ||

A Weibull distribution with Arrhenius relationship is used. The Arrhenius relationship uses the following formula | A Weibull distribution with an Arrhenius life-stress relationship is used. The Arrhenius relationship uses the following formula: | ||

| Line 17: | Line 17: | ||

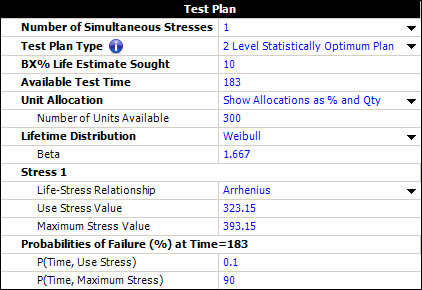

The planning values of the model parameters | The planning values of the model parameters for the test plan are <math>\beta\,\!</math> = 1.667, <math>\beta_{0}\,\!</math> = -16.7333 and <math>\beta_{1}\,\!</math> = 0.7265. These planning values were obtained based on the following assumptions: 0.1% of the units will fail in 6 months (183 hours) at 50°C, and 90% will fail in 6 months at 120°C. This information is given in Example 20.2 on page 535. | ||

The use temperature is 50°C (323.15°K) and the highest temperature used in the test is 120°C (393.15 °K). | The use temperature is 50°C (323.15°K) and the highest temperature that can be used in the test is 120°C (393.15 °K). | ||

A total of 300 units are available for testing | A total of 300 units are available for testing. The objectives of the test plan are to: | ||

* Determine the two temperature levels that | * Determine the two temperature levels that should be used in the test. | ||

* Determine the number of test units at each temperature level. | * Determine the number of test units at each temperature level. | ||

Tests will be conducted using the created test plan. The failure data from the test | Tests will be conducted using the created test plan. The failure data from the test will be used to estimate the model parameters, which will then be used to calculate the B10 life at 50°C and its variance. Therefore, we need a test plan that will minimize the estimation variance for the B10 life at 50°C. | ||

{{Reference_Example_Heading3}} | |||

The 2 level statistically optimum test plan is: | |||

* 212 units should be tested at 95°C (368.15 °K) | |||

* 88 units should be tested at 120°C (393.15 °K). | |||

Based on this test plan, the estimated standard error for the B10 life at 50°C is <math>Ase\left [log \left(\hat{t}_{0.1}(50) \right) \right] = 0.3794\,\!</math>. | |||

| Line 45: | Line 46: | ||

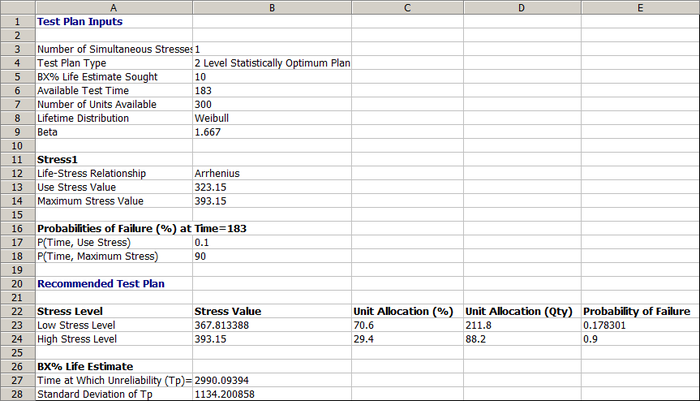

The resulting | The resulting test plan in ALTA is shown below. | ||

[[Image: Optimum plan one stress test plan.png|center|700 px]] | [[Image: Optimum plan one stress test plan.png|center|700 px]] | ||

This test plan shows that (starting at row 23 in the picture above): | |||

* The low stress level | * The low stress level should be 367.8°K (94.65°C) and about 212 units should be tested at this temperature. | ||

* The high stress level | * The high stress level should be 393.15°K (120°C) and about 88 units should be tested at this temperature. | ||

The results above are the same as the results given in the book. | The results above are the same as the results given in the book. | ||

The estimated standard deviation of the log B10 life at 50°C can be calculate | The estimated standard deviation of the log B10 life at 50°C can be calculate from the values given in the '''BX% Life Estimate''' area (row 26) of the results shown above. | ||

::<math>Ase\left[log \left(\hat{t}_{0.1}(50) \right) \right] = \frac{Ase\hat{t}_{0.1}(50)}{\hat{t}_{0.1}(50)} = \frac{1134.2}{2990.09} = 0.37932\,\!</math> | ::<math>Ase\left[log \left(\hat{t}_{0.1}(50) \right) \right] = \frac{Ase\left(\hat{t}_{0.1}(50)\right)}{\hat{t}_{0.1}(50)} = \frac{1134.2}{2990.09} = 0.37932\,\!</math> | ||

This is very close to the estimated standard deviation in the book. The difference is | This is very close to the estimated standard deviation in the book. The difference is likely due to rounding error. | ||

Latest revision as of 18:23, 28 September 2015

New format available! This reference is now available in a new format that offers faster page load, improved display for calculations and images and more targeted search.

As of January 2024, this Reliawiki page will not continue to be updated. Please update all links and bookmarks to the latest references at ALTA examples and ALTA reference examples.